Metal

Our metal technologies include machining, punching, die-casting and sheet metal technologies, such as punching, laser cutting and bending. Our experience in metal arches over 50 years.

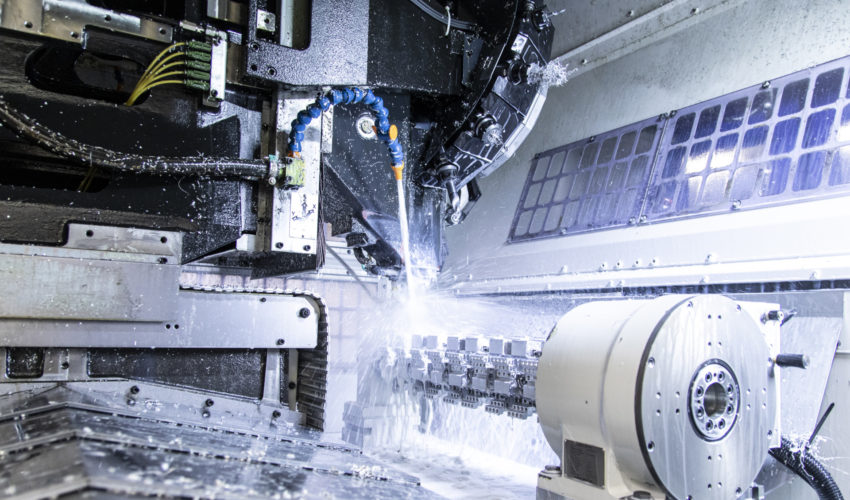

Machining

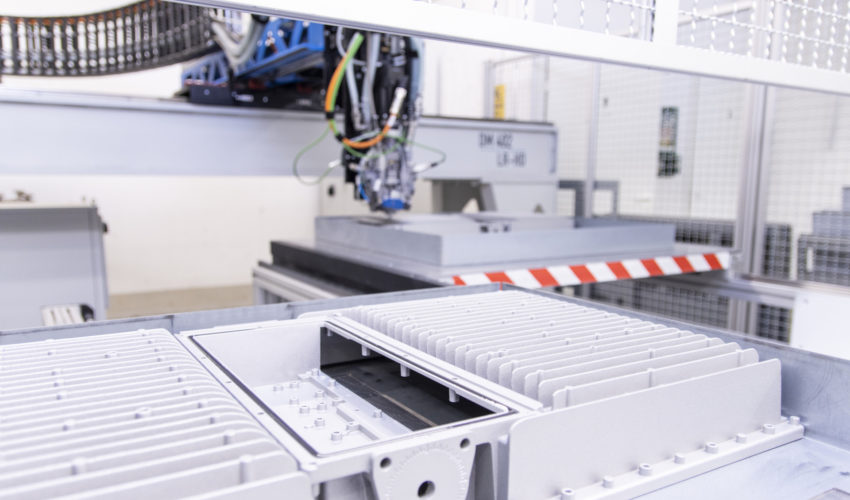

We have strong and broad competence in machining. Machining can be used as a further processing stage for die-casted components and for products that are refined from billets. Systematic production development, investments and our high level of automation ensure the efficiency of the manufacturing.

Machining includes milling and turning. CNC-machines for milling and turning enable the manufacturing of complex items. The most common metals such as steel, aluminium and copper can be used as materials. The machined pieces can be from small to middle-sized.

Machining services are offered by Ouneva and Alsiva.

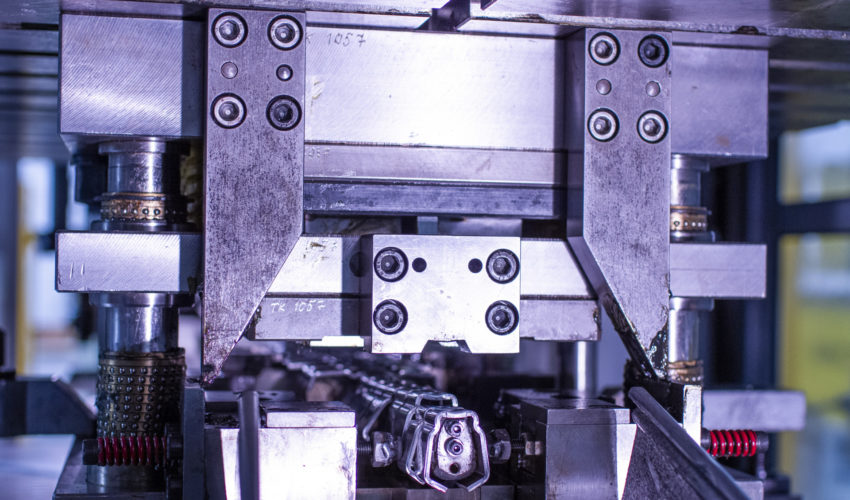

Punching

Ribbon-shaped metal reel punching is done with progressive cutting dies. The eccentric press machines have the power of from 18 to 200 tonnes. Material waste is minimised with the ribbon-shaped material, that naturally reduces the carbon footprint of the product. Because the punching manufacturing process includes fewer stages with different equipment, it is a considerably more cost-effective production method comparing to multi-machine technologies. The maintenance of the tools happens in our own factory.

Punching services are offered by Valukumpu.

Punching and laser cutting of sheet metal

You will find an efficient and diverse machinery for manufacturing different sheet metal products at Ouneva Group. With our sheet metal machinery, we manufacture highly refined products, as well as billets for further processing. The diverse technology options with our machinery, such as punching, laser cutting, shaping and threading and the high level of automation enable the smooth refining of items cost-effectively. Loading and unloading robots, that handle the raw materials and ready products add to the efficiency of the process. Our sheet metal machinery can handle material thicknesses from as little as 0,5 mm up to 8mm.

Sheet metal technologies are offered by Ouneva.

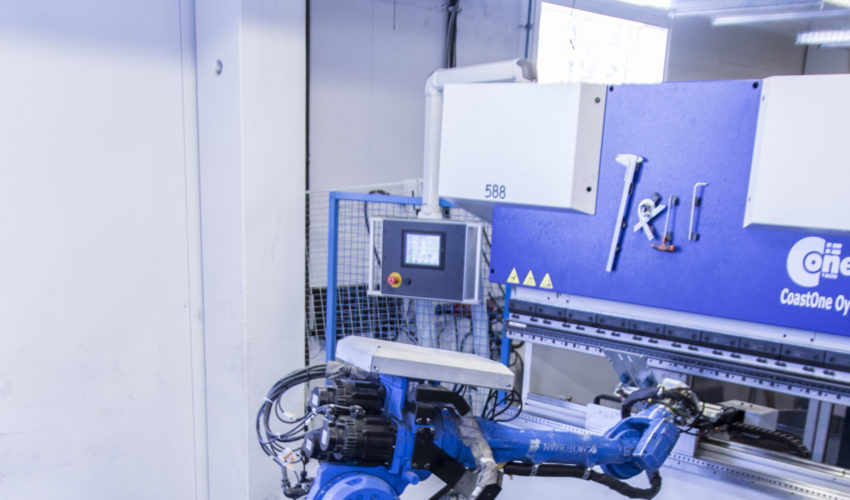

Press-brake bending

In sheet metal work, bending is a process included in almost every single one of the products we manufacture. With our bending machinery, sheet metal products can be shaped into enclosure-like or otherwise shaped structures, that can be further processed into complex final assemblies. Our diverse press-brake bending technologies enable efficient bending with smaller or larger items, independent of the complexity of its shapes. With bigger volumes we utilize robotic bending, that ensures the stable and high quality throughout the big batches.

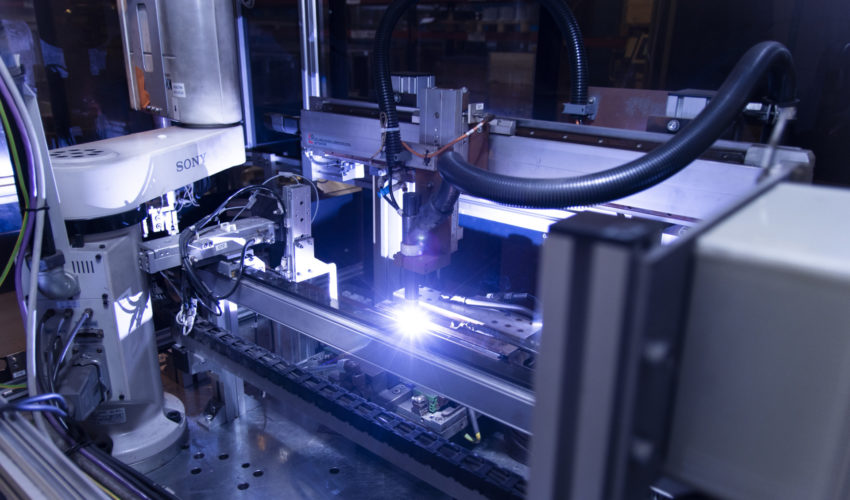

Welding

Welding is our most used joining technology in the manufacturing of sheet metal products. Our welding expertise entails MIG, MAG and TIG welding, as well as spot and bolt welding. Our strong knowledge in welding for different materials guarantees, that our customers can choose the materials required for the usage environment of their products without restrictions. Finishing and detailing the welded products is a significant part of the work we do at our welding department. Almost all of the welded products require high visual quality after welding, or the following powder coating. Our strong expertise in automation technologies ensures the efficiency in large volumes with automated welding solutions.

Inserts and fasteners

Different inserts and fasteners are typical components in sheet metal and die-casted products. Adding fastening points with threaded inserts enables a strong and durable mechanical fastening for thin material. When the material is thin, the insert is pressed into the item instead of machining or shaping production methods, forming a very strong fastening point. For installing the inserts or fasteners, we use special tools or machinery, whether it is a thin sheet metal product or a die-casted component.

Die-casting

The die-casting technologies of Ouneva Group focus on aluminium and zinc die-casting. In addition to the casting process, we offer different finishing services such as machining, blasting, different grinding solutions and powder coating. Different assembly solutions are a part of our offering as well.

All of our die-casting services are provided by Alsiva.

Aluminium die-casting

Aluminium die-casting is a versatile manufacturing technology. In Ouneva Group, the most common materials are AlSi10Mg and AlSi9Cu3. Our machinery is very diverse, ensuring capability and efficiency with small and larger products. Our biggest die-casting machine has the closing power of 900 tonnes.

The typical weights of die-casted products in our factory can vary from 20 grams up to 7 kilograms, with the surface area under 1800 cm². The benefits of aluminium in die-casted items are dimensional accuracy, strength and durability. The material is fully recyclable, which enables an environmentally friendly lifecycle for the product. The material waste can be minimized as well through the optimization of the casting process. Aluminium has excellent conductivity for heat and electricity, and the AlSI10 material is very corrosion resistant. To sum it up, aluminium as a material is very versatile and vivacious, in challenging conditions as well.

Zinc die-casting

Zinc die-casting is suitable for products, that require strong mechanical durability. A typical material we use is Zamak 5. The largest closing power of our zinc die-casting machinery is 60 tonnes, with the product weights between 2 grams up to 1 kilogram. The surface area is limited by machine size, to around 150 cm². Zinc die-casting is an excellent manufacturing method for large volumes and for small, dimensionally accurate mechanics parts. The material allows thin walls and minimal drafts in the items. The manufacturing tool is very long-lasting comparing to aluminium and the material has good surface treatment properties.

Sealing

Sealing solutions for die-casted and sheet metal products are a part of our broad offering. We use polyurethane (PUR) as a sealing material, that is an excellent sealant creating a fully leak-free seal. Sealing is an important manufacturing stage for products, that need good protection against for example challenging weather conditions. PUR sealing is a better alternative to adhesive tape, because it does not leave even the smallest gap, from where moisture could get into the inner structures of the product. With our automated sealing technology, we can reach IP 67 class sealing. The automation adds efficiency and keeps the quality uniform.