Electronics

The manufacturing technologies for electronics are highlighted in our production of PCBAs, electronic devices, wire harnesses, switchboards and electrical systems. The production includes the assembly and testing of the product in additional to the manufacturing. Our technologies enable the manufacturing of special high-quality products as well as broad box build assemblies.

Manufacturing of electronics in Ouneva Group happens at Jotwire, and at Eswire and Electro-Hill, that are located in Estonia.

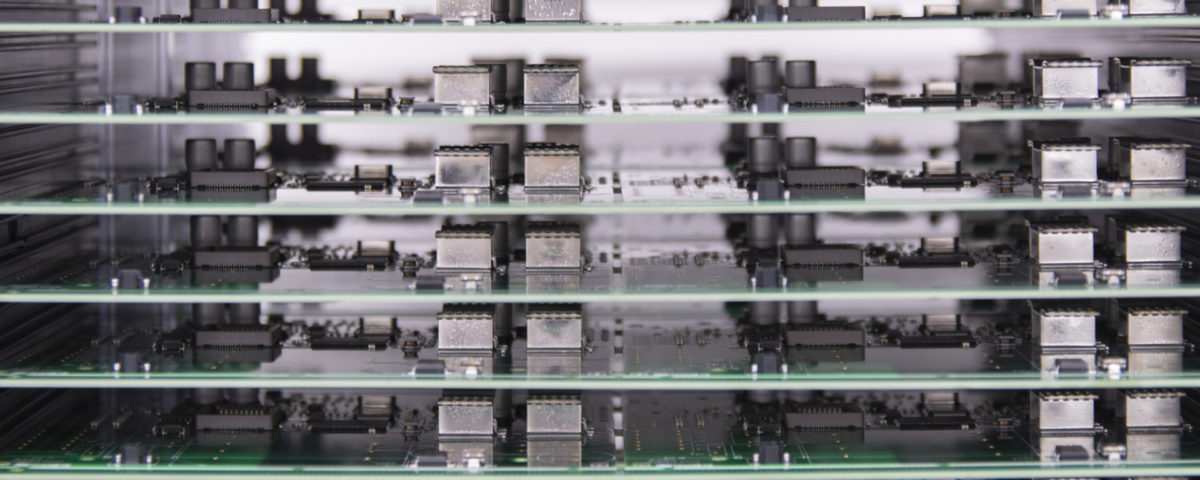

PCBA (printed circuit board assembly)

We use modern SMT lines with a diverse capacity. The production spaces comply with ISO class 7 clean room requirements, and their conditions are monitored constantly. The clean room spaces are also suitable for the production of medical devices.

Our automated SMT lines include automatic solder paste inspection machines, precise placement machines for SMT components (max 60 000 cph), automated optical inspection units and laser marking for product traceability. In addition, we have an x-ray inspection machine to ensure the quality of the soldering for BGA components. The accuracy of the precise placement machines enables the manufacturing of densely packed, as well as bigger PCB’s. The product applications can vary from small handheld devices to bigger assemblies.

In addition to our SMT lines, we offer manual mounting for THT components. The soldering solutions in our portfolio are selective soldering, wave soldering and manual soldering. The manufacturing of electronics can be complemented with product-specific automation solutions with soldering, assembling or testing. In addition, we provide a broad selection of highly developed protection solutions for electronics, such as potting in an open mould (epoxy, silicone, urethane), hotmelt moulding in a closed mould and parylene coating. Especially parylene coating is suitable for extreme conditions, providing the sensitive components with complete protection. Parylene coating can be used in diverse electronics applications from medical devices to products used outdoors, due to the excellent properties of the coating.

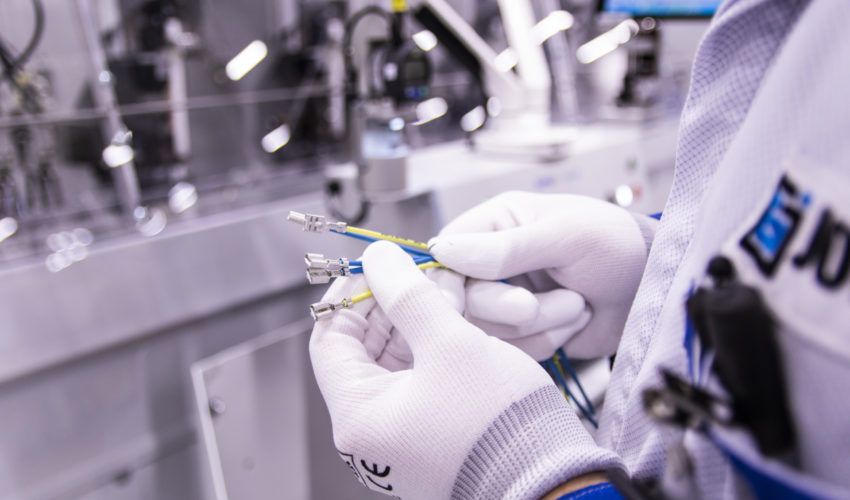

Wire harnesses & cables

We have a broad capacity and high level of automation in use for processing different wires and cables in a size range of 0,0123 – 120 mm2 (AWG 36 – 4/0). This production technology includes high efficiency with developed quality control, such as monitoring crimping power. Integrated measuring devices upkeep the traceability and quality of the products, as well as the whole production process. Different product tailoring and marking possibilities are integrated into the production line. Our joining technologies include crimping and thread inserts, as well as ultrasound welding.

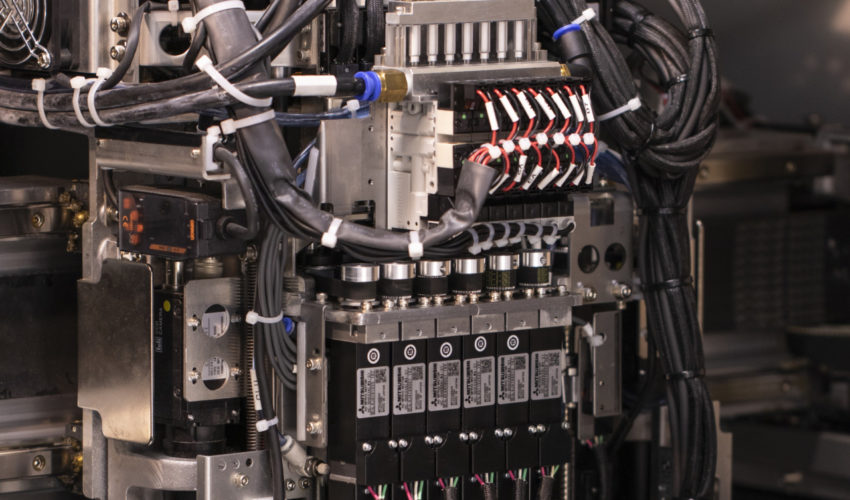

Assembly & electrical systems

Assembly is a significant part in manufacturing electronics and electrical systems. We can offer a wide scale of different options for assembly, taking the production volume into account. Our long experience in highly demanding electronics assemblies enable us to be very competitive, with products of excellent quality. Assemblies can be manual or automated, with our in-house automation team offering the best product-specific solutions. As well as with system assemblies, the diverse technology portfolio of the whole Ouneva Group is available for electronics assemblies, supporting the lifecycle-thinking and the requirements of the product.

The electrical systems that we manufacture can combine for example sheet metal components, wire harnesses and electromechanical components. Different enclosure solutions for special circumstances, control planes and other complex assemblies are a part of our offering. Our strong and diverse assembly competence enables the manufacturing of products used in very demanding environments. Advanced production automation ensures efficiency and creates the foundation for uncompromised quality. Due to our digitalised documentation system, we master changes and the exact details, that are required in electrical systems used in extreme conditions. Typically, the ready assembly is electronically tested before delivery.

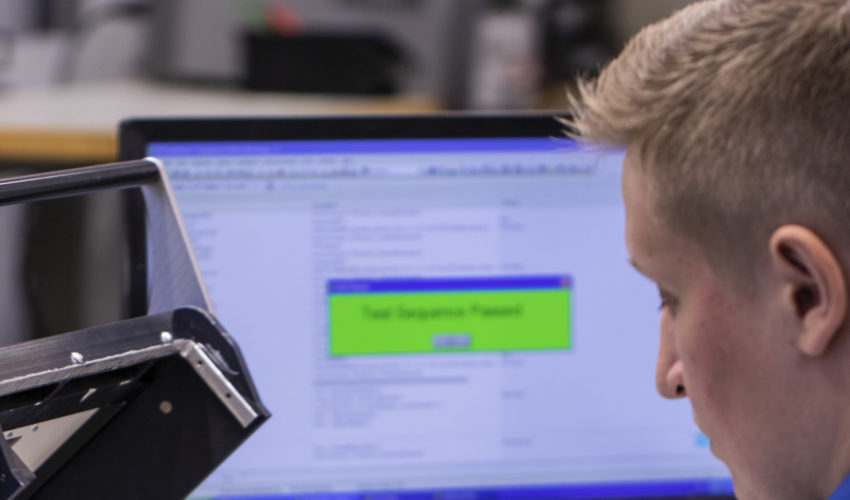

Testing

Testing is also an important part of the manufacturing process of electronics and electrical systems. Our in-house testing design expertise and a broad network of partners enable demanding testing solutions. For high-volume products, the automation of testing increases competitiveness. The integration of the customer’s own testing systems into the manufacturing process is possible. We offer testing for electronics and wire harnesses, as well as electrical systems. Our testing services include i. a. wiring testing, component testing, in-circuit testing, functional testing and software upload. Different testing related to sealing properties and electrical safety, as well as product-specific testing software (e.g. RF testing) are a part of our broad services.