Quality management from the viewpoint of our staff

Quality management is a systematic approach and a set of practices that organizations use to ensure that their products or services consistently meet or exceed customer expectations. Key components of quality management include setting and monitoring quality standards, continuous improvement, customer focus, and the involvement of employees at all levels in the pursuit of quality excellence.

We discussed quality management and what it means for our staff with three of our colleagues. From the management team, we had a discussion with Mika, the plant manager of Valukumpu. Our quality engineer, Likka from Alsiva, told us how quality management is reflected in her daily work, and on the production side, Heidi explained what quality means to her.

Clear processes support the everyday activities of Valukumpu’s quality organisation

At Valukumpu, quality production is based on systematic quality management. The quality manual defines clear practices, and close customer collaboration plays a significant role in quality management. According to Mika, our customers are very interested in how our processes work. We learn a lot from our customers, and the collaboration is highly reciprocal, especially concerning quality processes. Our goal is to make the entire supply chain work efficiently and in a high-quality manner.

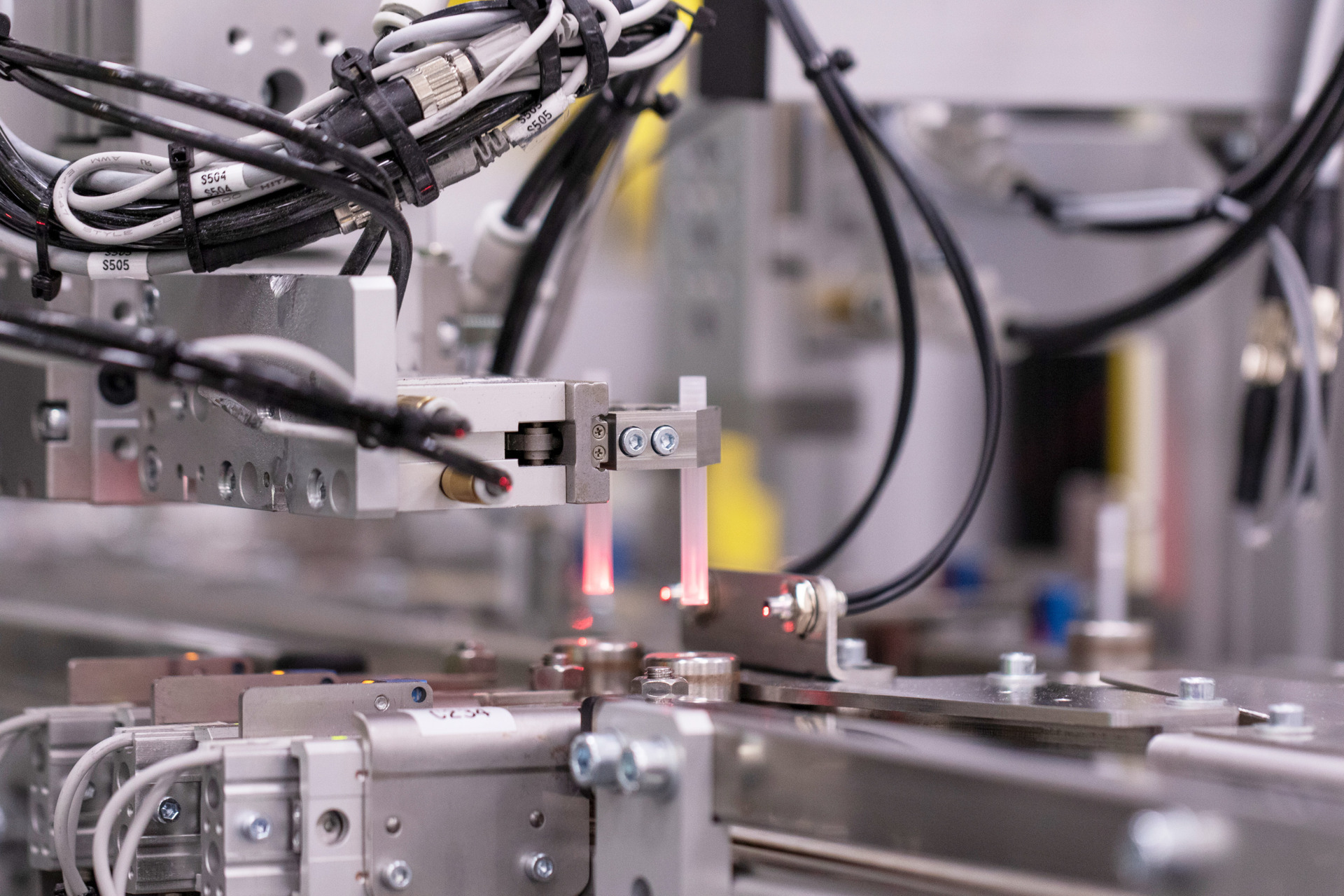

Valukumpu has extensive experience in manufacturing medical devices. Mika explains that the medical sector has provided valuable insights into how processes should be implemented. Other customer segments benefit from the industry’s strict quality requirements, and tailored solutions can be extracted from there for other customers. Leveraging technology based on our extensive experience is emphasized. Valukumpu has a competitive advantage in delivering high-quality solutions, thanks to its skilled automation department. According to Mika, Valukumpu possesses a deep understanding of demanding quality matters.

Quality production is the responsibility of all employees, and everyone is expected to address any potential deviations. The staff is supported by a strong quality organization that actively goes to the production, provides guidance when needed, and listens to everyday challenges. The quality organization continuously develops operations to provide the best possible support to employees. Regular meetings are held with the staff to discuss quality matters, during which deviations and challenges are reviewed based on data. The communication culture at Valukumpu is excellent, according to Mika. Issues can be constructively discussed, and the best solutions are found together.

Mika sees a positive future for quality management at Valukumpu. He emphasizes clear and easily adoptable processes, as well as active communication in that regard. In the future, the Group’s shared quality policy will be further developed. Internal audits are already part of our operations and our quality organizations from different companies meet regularly.

Quality relates to all we do

While talking with Alsiva’s quality engineer, Likka, the emphasis on quality being related to all aspects of operations became quite clear. According to Likka, quality is often perceived as something very narrowly focused, but when you see the bigger picture, you understand that quality matters are truly interconnected with every aspect of the company’s operations.

In Likka’s daily work, the bigger picture is strongly present. Likka finds it important to understand the challenges in daily operations and whether they require broader guidelines from the quality organization. According to Likka, she aims to support quality operations through her work by always addressing the challenges raised by the staff. It’s important to revisit what actions were taken and why they were taken. Likka emphasizes the importance of perseverance in ensuring that improvement ideas are implemented.

The staff plays a crucial role in both generating improvement ideas and throughout the daily activities. Likka stresses that the staff is the company’s most important asset. Production work is at the core of their work, which requires a regular clarification of the overall picture. In the quarterly meetings, Likka hosts the quality part with the production staff to explain what goes on behind the scenes in the quality organization and why things are done in a certain way. This ensures the staff’s understanding and commitment to high-quality operations.

Likka also sees a positive future for quality management. Following Mika’s lead, Likka envisions more collaboration within the Group and joint quality projects in the future. She has also observed a shift in the quality industry towards being more focused on personnel. Likka notes that Ouneva Group actively invests in unity, guiding operations appropriately while allowing enough freedom to develop them even further.

The value of quality is well realized

Heidi works as a sheet metal worker in Ouneva’s sheet metal production. We asked Heidi what quality management means in her work.

For Heidi, quality management as a production worker largely manifests as practical aspects. Products and pieces are regularly measured, and the measurements are carefully documented and reported. Quality matters, such as recent deviations, are discussed in regularly held team meetings.

It’s also important for Heidi to leave work satisfied with the quality of her work. Quality is a daily topic of discussion in production, so Heidi often leaves work with a sense of accomplishment. She mentions that a lot of different products are produced, and when it comes to new pieces, quality requirements are always carefully reviewed.

One of Ouneva Group’s values is quality. Heidi believes that this value is well realized within the Group. She particularly praises the fact that there’s no compromise when it comes to quality matters, and they are taken seriously. In the future, Heidi would like to see even more efficient quality training. She also considers the sharing of tacit knowledge to be highly important.

We implement quality management at Ouneva Group on behalf of our employees, using modern technology solutions. Providing high-quality products and solutions is the foundation of our operations.