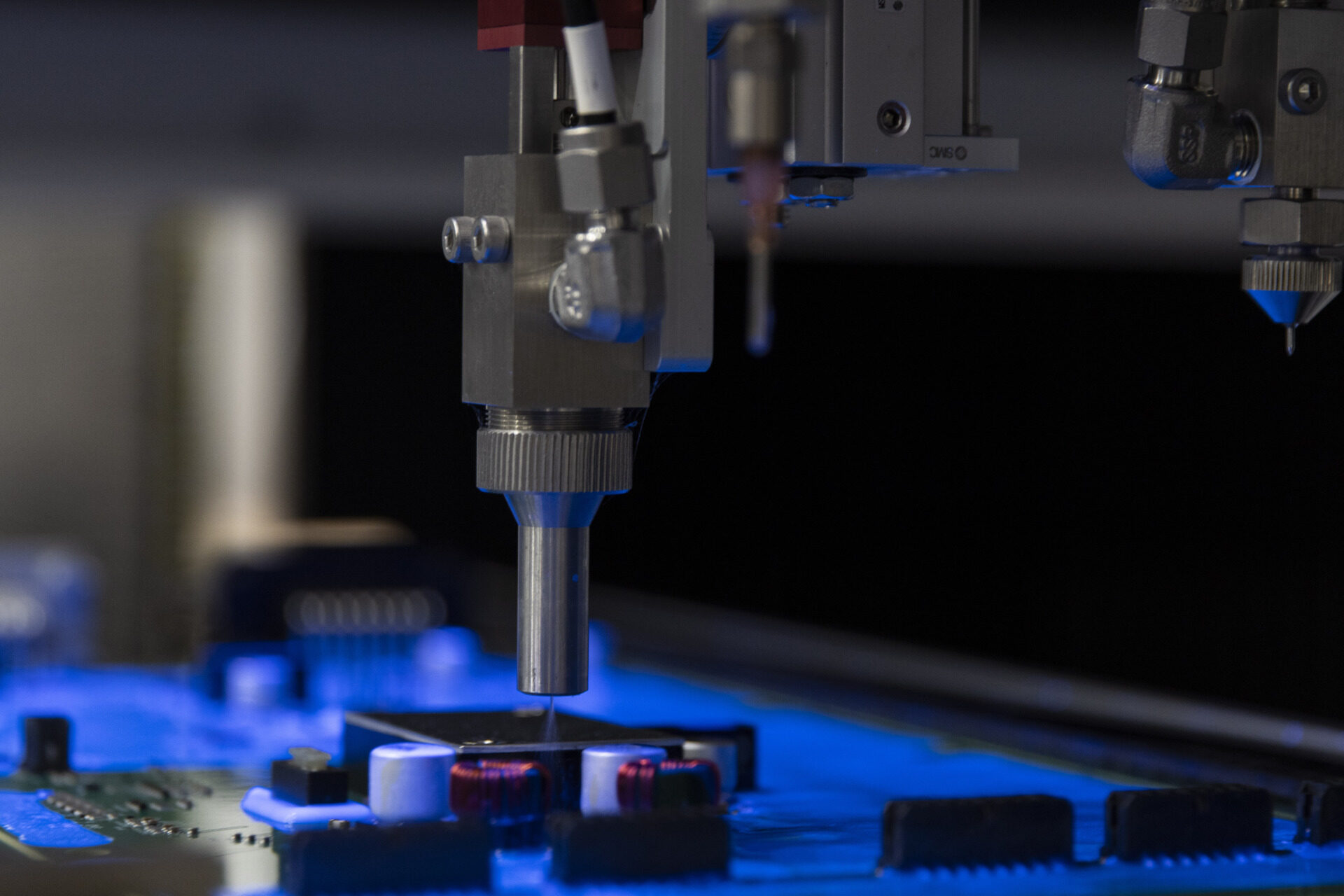

Jotwire’s new conformal coating line

An automated conformal coating line for electronics protection has been implemented at Jotwire. Protecting electronics is a critical step, especially in the manufacturing of electronic solutions used in challenging environments. Jotwire has strong expertise in conformal coating and electronics protection methods.

Why Protect Electronics?

Printed circuit boards (PCBs) consist of sensitive components whose functionality can be disrupted by factors such as moisture. Conformal coating shields components and circuit boards from various environmental factors. Well-coated electronics can withstand changing conditions and ensure reliable functionality in all operating environments. Conformal coating protects electronics from moisture, vapor, and chemical impurities.

Protecting Electronics with Conformal Coating

Conformal coating is one of the most common methods for protecting electronics. It can be applied manually, by dipping, spraying, or dispensing with automated equipment. There are various types of conformal coatings, selected based on the intended environment and components. Most coatings are made of acrylic or polyurethane-based materials, which provide excellent resistance to moisture and chemicals, depending on the type.

The first step in the coating process is masking. Masking materials can be applied to protect sensitive connectors and components, preventing the coating from spreading to areas where it is not desired. A robot then sprays the conformal coating evenly onto the surface of the circuit board, after which it is cured in an oven. Once dried, the coating surface is ready for quality inspection and delivery.

Benefits of Automated Conformal Coating

The clearest advantage of automated conformal coating compared to manual methods is consistency in quality. The thickness and precision of the coating are uniform when applied with automated equipment. The process is also fast, making automated conformal coating an excellent choice for high-volume production. Precise programming ensures short processing times for demanding products. Additionally, automated conformal coating results in minimal material waste thanks to highly accurate spraying.

Key Advantages of Conformal Coating:

Below, you can see our new line in action. We offer contract manufacturing of electronics backed by decades of experience and deep industry insight, including the latest protection technologies. You can easily reach our experts through our contact form.