Cycle of plastic material

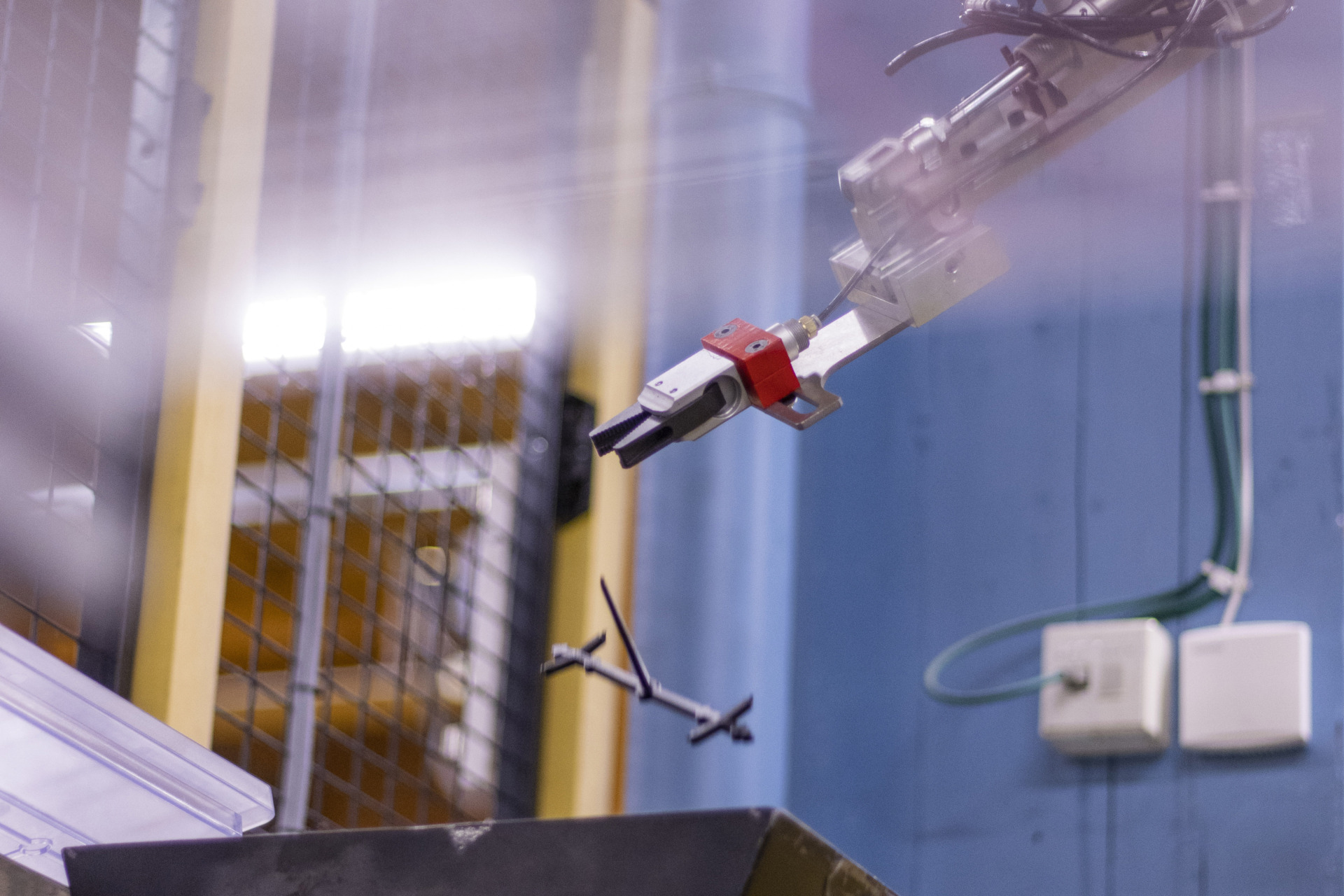

When walking around in the production of Valukumpu, you can see pairs of robots working together. Valukumpu offers all of the plastics technologies in Ouneva Group. The robot extends its grabber and removes the freshly injection-moulded item from the mould, but instead of dropping it to a packaging box or taking it to the next production stage, it is taken towards the waiting plastic scrap crusher. The surplus material, that mostly consists of the runner, is dropped into the crusher. They process the surplus material into granulate, that is collected and reused in our own production.

The crushers reduce the amount of material waste in the production. For us, they also mean lower material costs. At the same time, we enable an internal cycle for the plastic material, that would otherwise go to waste. The crushers are easily set up in automation units and they are applied in the units always when it’s possible.

Plastic component manufacturing needs? We’ve got you covered, let’s get in touch!